ABOUT US

About Us

ABOUT US

Business Process

To meet customer demand for packaging continues to rise, strengthen the rapid response of the system.

It is our most important mission to turn customers' ideas and expectations into reality, that is, to provide consumers with the selected packaging in a high quality, assured and safe form.

In order to achieve the above goals, we draw on the views of customers, planning, sales, design and other departments are based on quality management, to build a production high quality, high-function packaging of the overall production of physical.

| |

|

NO.2 Development Design When developing the design, the main consideration is whether the designed product is suitable for the important elements of the market strategy. Our company uses computers to design packaging drawings and has the design physique to meet all customer requirements and intentions for goods. |

| |

|

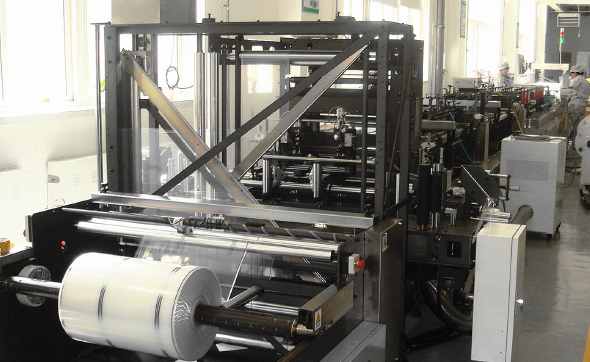

NO.4 Printing Unique printing technology, the use of flexible corresponding to a variety of packaging materials gravure printing, nine-color printing machine to make colorful performance possible. |

| |

|

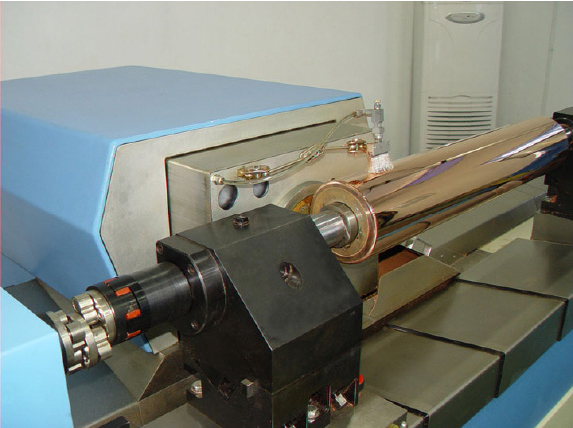

NO.6 slitting Fully automatic production line, the film roll tension after slitting can be automatically adjusted according to the material and setting, and the electronic deviation correction tracking system can be prepared for positioning. Ensure that the end face after high-speed slitting and winding is error-free, flat and smooth. |

| |

|

NO.8 Quality inspection Strictly according to the requirements of ISO9001 and 6S management. Self-inspection, process pumping, final inspection and shipment inspection of incoming raw materials and products and keep inspection records. |